Pre-delivery inspections (PDIs) are vital for ensuring vehicle quality and safety before ownership transfer, identifying issues like structural damage or faulty mechanics. Technology integration, including digital cameras, 3D scanning, and AI software, revolutionizes PDIs by providing detailed documentation, reducing human error, and streamlining processes. These advanced systems boost efficiency, accuracy, and customer satisfaction in the automotive industry.

In the dynamic world of logistics, a Pre-Delivery Inspection (PDI) is more than just a checklist. It’s a critical step ensuring product quality and customer satisfaction before goods reach their final destination. This article delves into the essence of PDIs, exploring how technology integration dramatically enhances efficiency and accuracy in these initial assessments. We uncover the multifaceted benefits of combining traditional inspections with modern tech tools, highlighting how this collaboration drives success across industries.

- Understanding Pre-Delivery Inspection: The Initial Assessment

- Technology Integration: Enhancing Efficiency and Accuracy in PDIs

- Unlocking Benefits: How PDIs and Tech Collaboration Drive Success

Understanding Pre-Delivery Inspection: The Initial Assessment

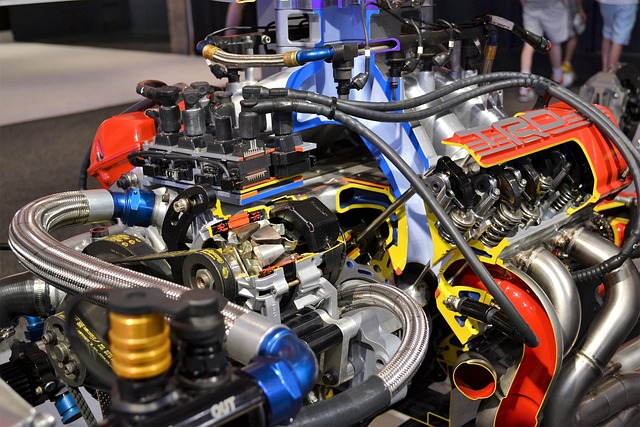

The pre-delivery inspection is a critical step in ensuring the quality and safety of vehicles before they reach their intended owners. It involves a comprehensive assessment of various components, from external bodywork to internal systems. This initial evaluation by experts identifies any potential issues or defects that may have occurred during manufacturing or transportation. By conducting thorough pre-delivery inspections, buyers can gain valuable insights into the overall condition of the vehicle.

This process is particularly essential for discerning car enthusiasts and those seeking reliable auto repair services. It allows for early detection of problems that could later turn into costly repairs, such as structural damage, paint imperfections, or faulty mechanical parts. Moreover, understanding the benefits of pre-delivery inspection empowers buyers to make informed decisions, ensuring they receive a vehicle in prime condition and potentially avoiding post-purchase headaches related to auto frame repair or automotive collision repair.

Technology Integration: Enhancing Efficiency and Accuracy in PDIs

Technology integration is transforming pre-delivery inspections (PDIs) by significantly enhancing efficiency and accuracy. Modern tools like digital cameras, 3D scanning, and AI-powered software enable detailed documentation and analysis of vehicle conditions, ensuring a comprehensive assessment. For instance, high-resolution images captured during PDIs can be stored in cloud-based systems, facilitating easy access for both mechanics and clients.

This integration goes beyond visual inspections. Specialized sensors and diagnostic tools integrated into PDIs can detect subtle issues, such as uneven tire wear or minor paint repairs needed, that might otherwise go unnoticed. By leveraging these technologies, auto body repair shops and dealerships can streamline their processes, reduce human error, and ultimately provide a higher level of service. This translates to faster turnaround times for vehicle preparation and increased customer satisfaction, making technology integration a game-changer in the automotive industry’s pre-delivery inspection practices.

Unlocking Benefits: How PDIs and Tech Collaboration Drive Success

Pre-delivery inspections (PDIs) are a pivotal step in ensuring the quality and condition of vehicles before they reach their final destinations. By meticulously examining every aspect, from the vehicle’s bodywork to intricate components, PDIs identify any defects or damages that may have gone unnoticed. This proactive approach not only enhances customer satisfaction but also sets the stage for successful integration of advanced technologies.

When coupled with technological advancements, PDIs transform into powerful tools for efficiency and precision. For instance, digital inspection systems enable detailed documentation and real-time data sharing, streamlining processes in automotive body shops. Vehicle paint repair, a critical aspect often subject to human error, benefits from computer vision algorithms that accurately detect variations and imperfections. This collaboration between human expertise and technology promises improved outcomes, reduced turnaround times, and enhanced overall vehicle quality, ultimately driving success in the automotive industry.

Pre-delivery inspections (PDIs) are a pivotal step in ensuring the quality and safety of goods before they reach customers. By integrating technology into these processes, businesses can achieve unprecedented efficiency, accuracy, and transparency. This article has explored how understanding PDIs, leveraging advanced technologies, and collaborating across departments drive success in various industries. Embracing these practices not only enhances customer satisfaction but also positions companies as leaders in their respective markets.